Corrugated Walls

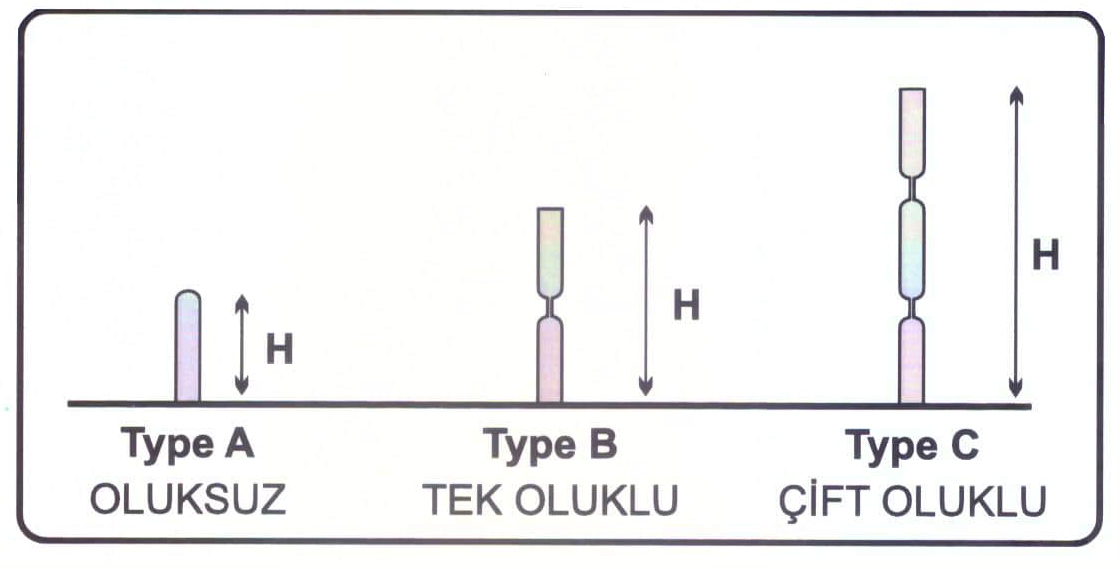

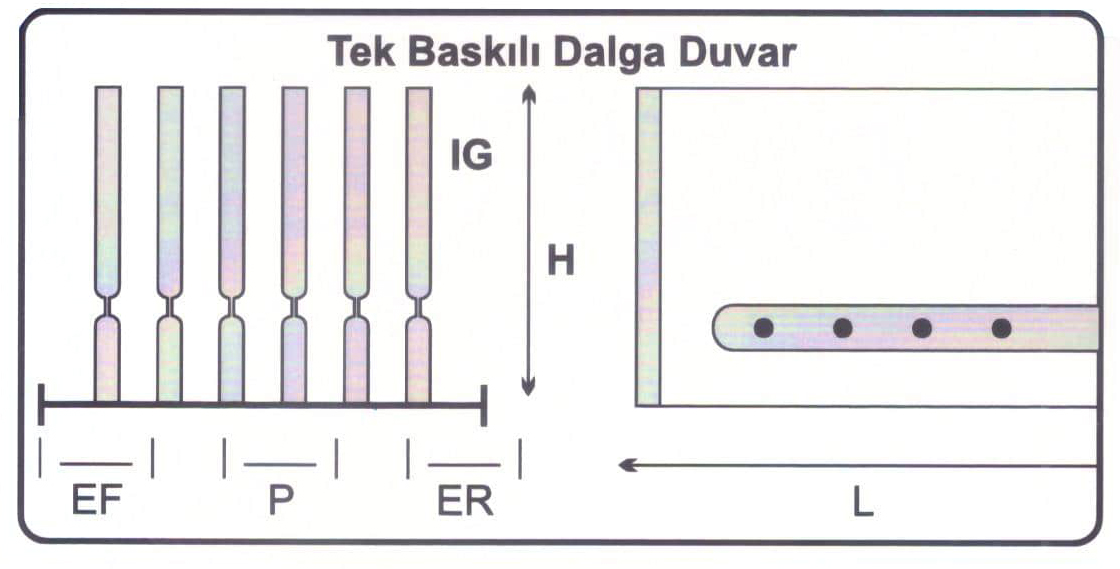

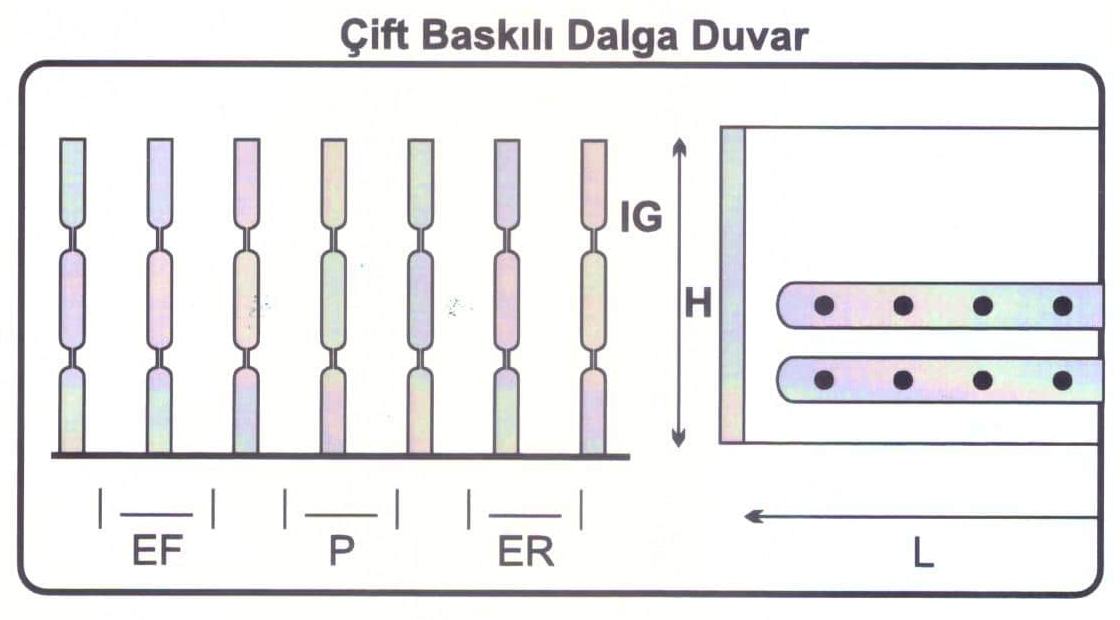

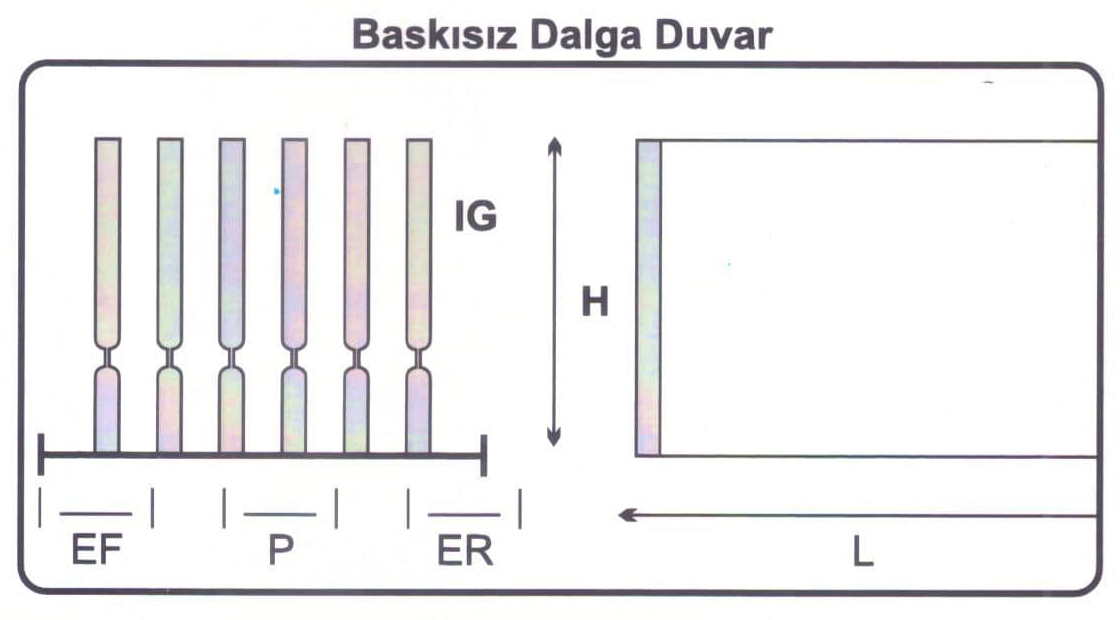

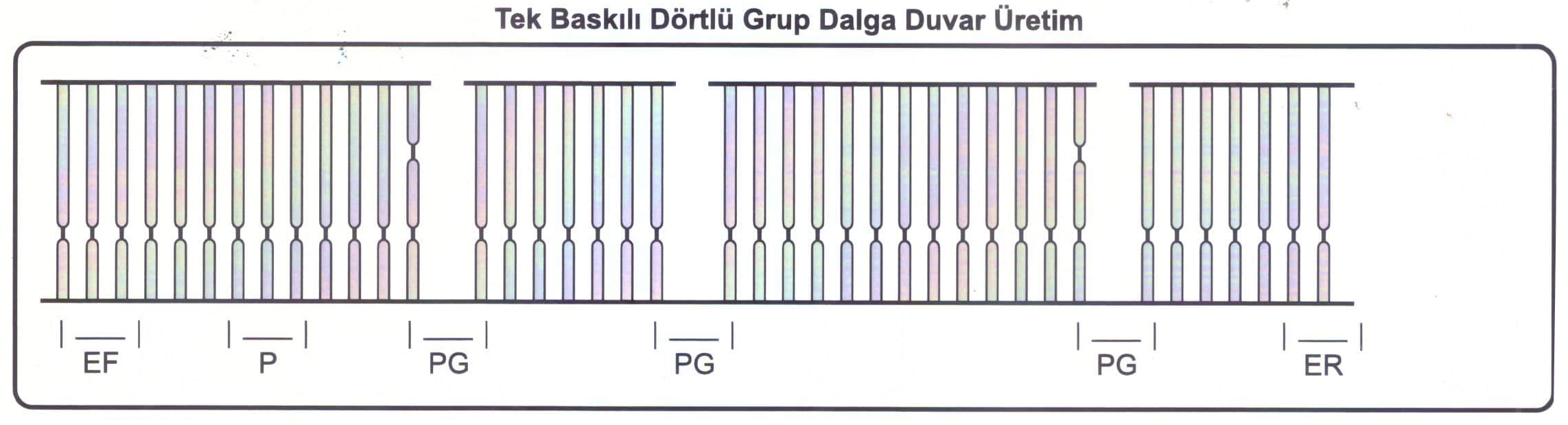

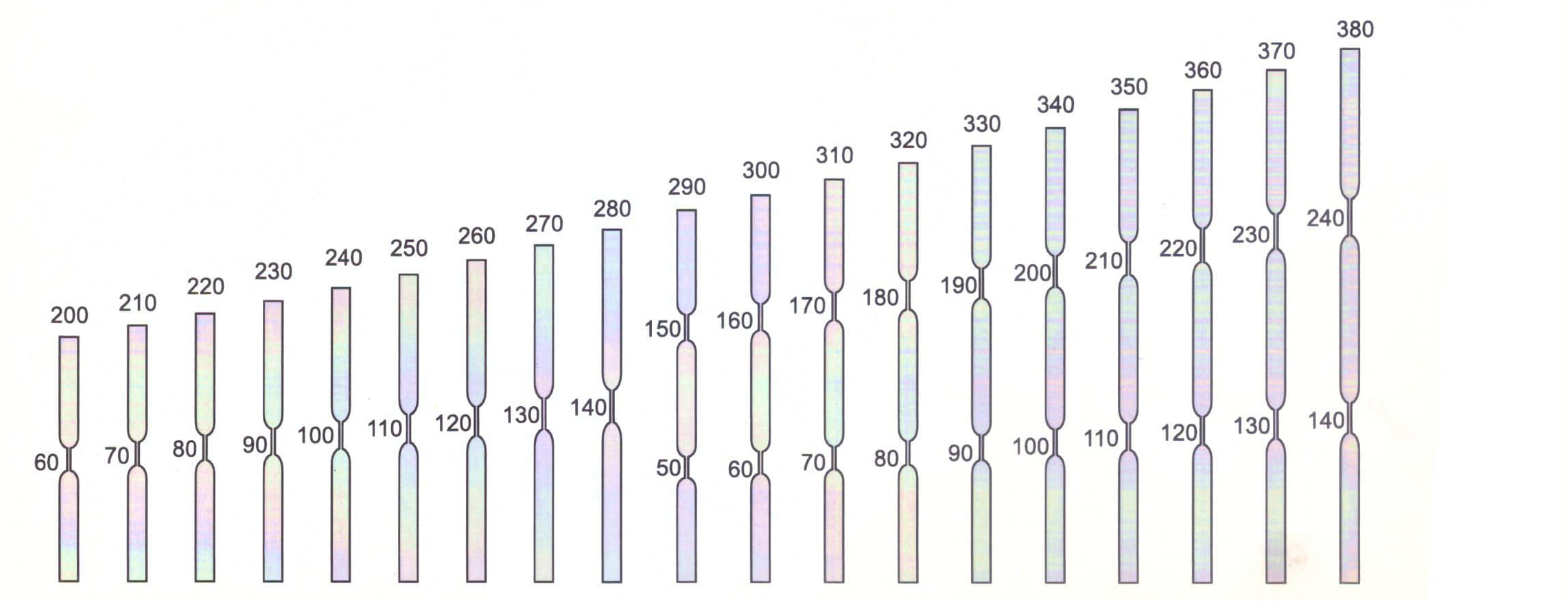

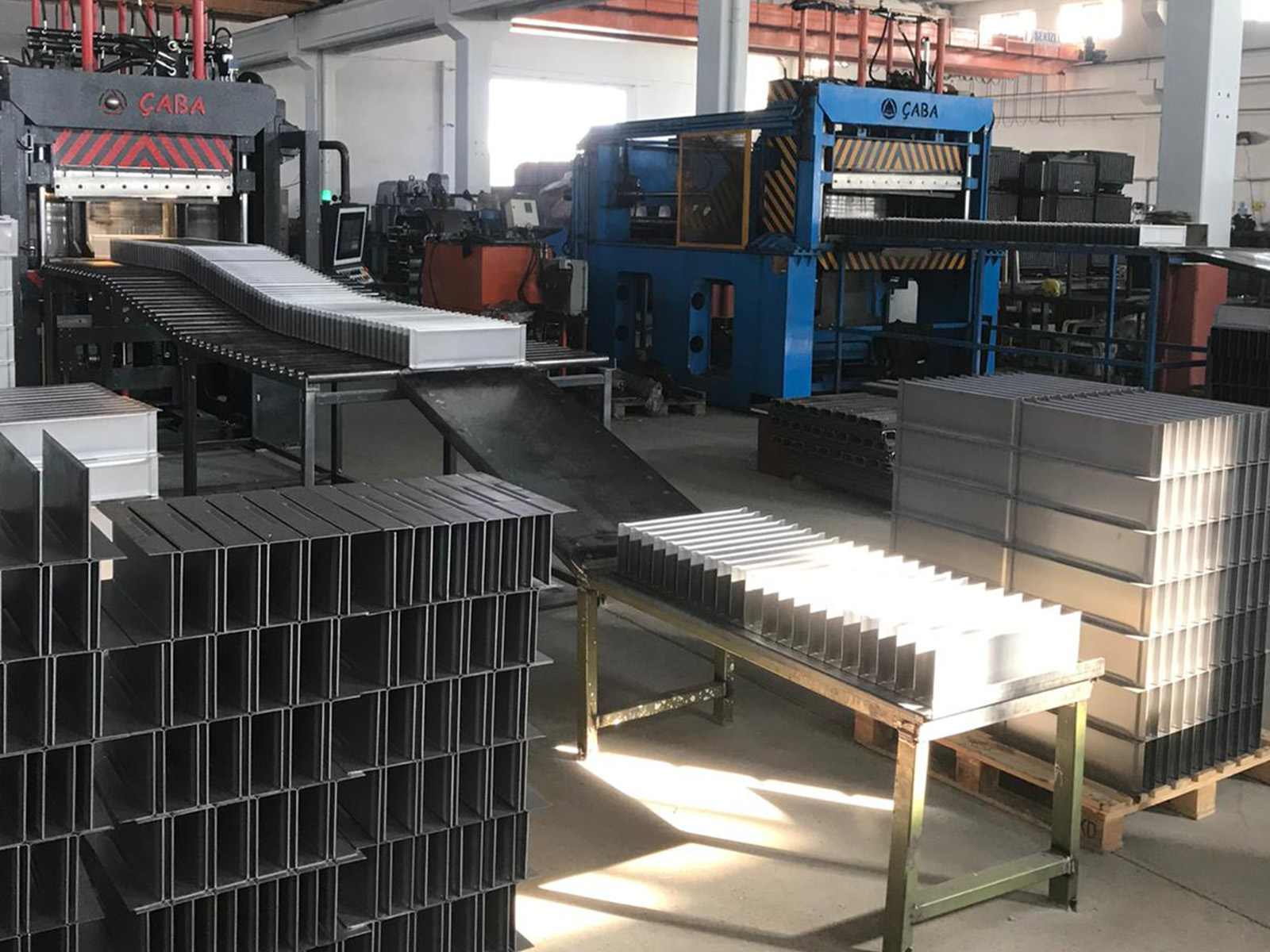

Transformer cooling elements that are made into cooler cores by processing the rolled sheet, and adapted to the desired dimensions with a corrugated wall machine are called Corrugated Walls. It is used to provide a quicker cooling by increasing the contact surface of oil with air. Corrugated Walls are produced from CCR6112 – A/1 quality cold rolled sheet as a single piece with a thickness of 1.20-1.50 mm in Automatic Corrugated Wall Machine according to customers’ request.

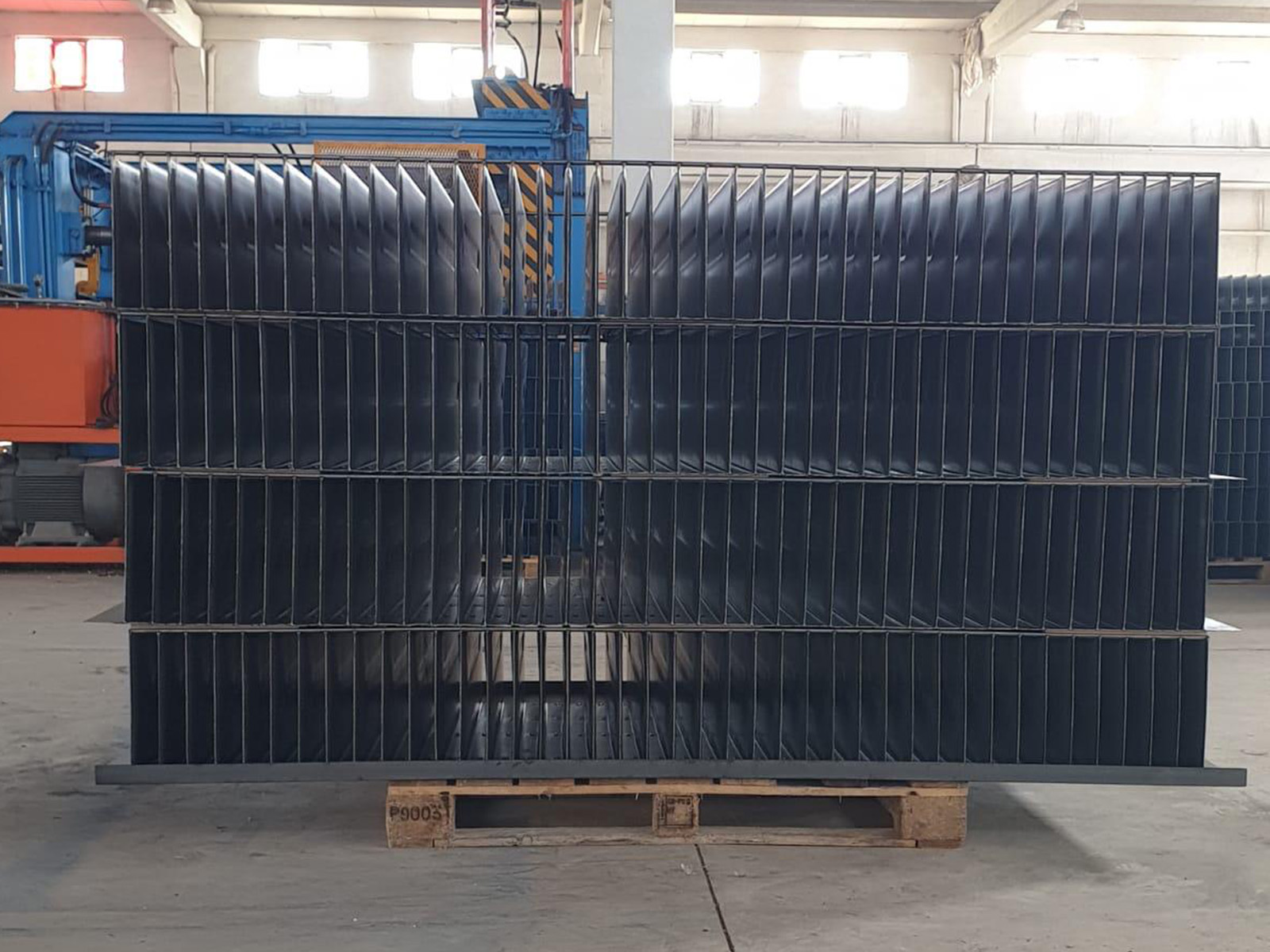

After the products are produced by CNC Corrugated Wall Making Machine according to the technical drawings prepared to suit the customer's request, the edge welding, transmission welding and support belt welding process begins by gas metal arc welding machine and then proceed to Testing Department. The corrugated walls, which successfully complete the necessary tests, are packed on suitable pallets and made ready for shipment.